by Jonathan Tucker, Senior Marketing and Product Manager, Keithley Instruments, Inc., Solon, Oh.

Changing user expectations are shaping test instrument graphical user interface (GUI) design.

User expectations for new instrument interfaces are changing. For instrumentation vendors, successfully designing new instruments means understanding that although users still need accurate measurements, they rarely have unlimited time to learn how to use new tools effectively. As the time available to make decisions based on test and measurement results continues to get tighter, a growing number of users will demand that their instrumentation deliver answers quickly without compromising measurement integrity.

As a result, test instrument design is poised to undergo some striking changes during this decade. To gain perspective on some of these changes, it may be useful to look back at how instrument interface designs have evolved over the last half-century as new display technologies have been developed.

In the mid-20th century, interacting with instruments was typically anything but a seamless process. Configuring a measurement typically required twisting dials to select the desired functions and set ranges. “Taking data” often required manually transcribing readings from an analog dial or measuring traces from a strip chart recorder printout.

The development of LED and LCD digital readout displays marked the first major innovation in user interface design. Function and range setting knobs were increasingly replaced with push-button controls, which expanded the user interface beyond simply configuring ranges and functions. Users no longer depended on paper and pencil to capture data after the first communications interfaces, such as RS-232 and GPIB, were added to instruments to support system integration and triggering, remote programming and control, as well as transfer of data to external controllers for analysis and display.

By the 1990s, users had begun to demand increasingly detailed information on their measurements, such as the level of current being sourced to the device under test, voltage limits, and error messages. This demand eventually led instrument makers to begin developing brighter, easier-to-read, multi-line vacuum fluorescent displays that could display multiple measurements simultaneously from a single measurement connection. This new display capability also made it possible to present measurement results in more intuitive ways, such as in a bar graph. To allow users to configure the display settings and performance options, vendors often assigned multiple functions and performance options to the same front panel button.

Recent Trends

A growing number of electrical test instrument manufacturers have begun to focus on providing interfaces that offer users a faster time-to-answer, including instruments with embedded test software that can provide a significant boost in testing productivity. With this virtual front panel approach, all that’s necessary is to connect the instrument to the Internet via a LAN cable, open a web browser anywhere in the world, type in the instrument’s I.P. address, set up the measurement using simple on-screen configuration tools, and begin testing.

Recent industry studies have highlighted significant changes in the test market, including shrinking product design cycles (down by 13% over the last three years), which have made achieving that faster time-to-answer more critical than ever. This new urgency to get more done faster is also, to some extent, the result of changes in who is responsible for test and measurement functions today. Companies are employing fewer dedicated test engineers. At the same time, however, the profile of the typical instrument user has broadened. In addition to electrical engineers, it now includes a growing number of engineers from other disciplines who need fast access to test data but may have limited training in electrical measurement. A growing number of these users have a greater focus on software than on hardware. For these newer users, traditional button and command menu interfaces can present some significant challenges.

Changes in user characteristics and expectations about ease-of-use have led instrument manufacturers to create user interfaces that incorporate many of the same control and display innovations that have revolutionized consumer products like tablets, smartphones, and cameras. The most prominent of these innovations is the use of advanced capacitive touchscreens with multi-point, pan-pinch-zoom-swipe operation. Touchscreens support faster learning than other control and display approaches. By providing immediate visual feedback, they can also give users more confidence in what they’re doing, drastically reducing user learning curves and training requirements while improving accuracy and efficiency.

A recent survey conducted by Keithley among its customers uncovered some important insights into their concerns and desires about the next generation of instruments. Among the findings were that users wanted:

• a simpler interface

• to speed up the measurement process significantly

• to be free to focus on their work, rather than on the details of the test or measurement process.

The newest test instrument designs have begun to reflect these customer concerns. For example, the Keithley Model 2450 SourceMeter Source Measure Unit (SMU) Instrument provides a capacitive touchscreen interface that speeds up the measurement process by helping users test accurately and get results quickly, and allows them to focus on measurements and data rather than on learning how to configure the instrument. With simplified setups configured from the front panel, such instruments support faster time to measurement and significant improvements in test productivity.

The intuitive nature of touchscreen interfaces lets users at all levels of testing sophistication become experts quickly. They also offer the advantage of providing instant access to on-board help, which eliminates the need to consult a user manual to get an instrument up and running.

There still may be some doubt about whether touchscreen interfaces are for everyone or only for novice or infrequent users. After all, they might reason, some experienced instrument users may hesitate to make the switch to touchscreen technology because they’re accustomed to working with front panels with buttons, keys, and knobs and need the tactile feedback that pressing a button or turning a knob provides. However, the addition of a touchscreen to the interface doesn’t preclude incorporating buttons and knobs as needed. Touchscreens can display results using larger, more legible numerals, provide more details about the measurement, and provide on-screen data graphing capabilities never before available. Also, because touchscreen displays are software defined, they’re easily changed to reflect the different controls and indicators required for different applications, freeing up valuable real estate on the instrument’s front panel. The intuitive nature of touchscreen-based interfaces can also drastically reduce training time, increase operator accuracy, and improve overall operational efficiencies, which helps drive down the cost of ownership.

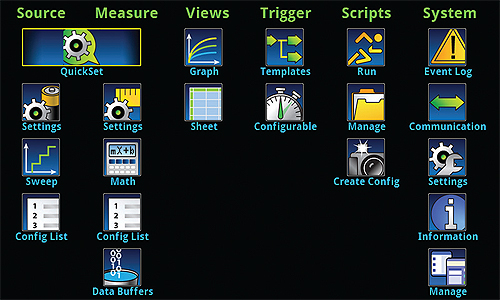

Many test instrument vendors continue to design instruments with multi-level menu structures, which can be confusing to navigate. Instruments that use soft-key architectures sometimes force users to go as many as six layers deep to reach the desired selection. In contrast, a touchscreen GUI eliminates this confusion with a flat menu architecture that ensures any configurable parameter is just two on-screen touches or pushbutton presses away. The main menu screen represents many functions and parameters graphically, allowing for more intuitive operation and reducing the number of configuration setup steps required. For example, to create a simple current vs. voltage (I-V) sweep, the user simply presses the front-panel MENU button, then selects Sweep from the Source column. There’s no need to go back and forth between multiple displays and menu levels.

Keithley Instruments, Inc.

www.keithley.com

Leave a Reply

You must be logged in to post a comment.