The midUTS from Bloomy contains a multimeter, data-acquisition, switching, and power supplies for testing boards and systems.

Automating tests — whether for bench testing new designs, in production, or for service — increases productivity but comes at a price. If you’re going to build an automated test system all yourself, expect to specify the instrumentation, define the switching and signal routing, build test fixtures, define the tests, and write the software. The midUTS from Bloomy can ease some of that pain.

Automating tests — whether for bench testing new designs, in production, or for service — increases productivity but comes at a price. If you’re going to build an automated test system all yourself, expect to specify the instrumentation, define the switching and signal routing, build test fixtures, define the tests, and write the software. The midUTS from Bloomy can ease some of that pain.

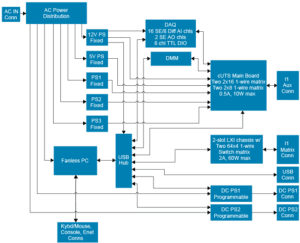

Standing for mid-range universal test system, the midUTS integrates instruments such as a 6½-digit DMM, a multifunction data-acquisition system (analog and digital input/output and a counter/timer), switching, relays, and up to three power supplies (5 V, 12 V, ±15 V, 24 VDC up to 5 A each).

The system block diagram shows how the midUTS main board holds switching matrices and relays that connect your DUT to the test instruments. For testing board assemblies, you’ll need a bed-of-nails test fixture to contact a board’s test points, then the switches route signals to and from the instrumentation. An internal fanless PC runs Windows to control the tests.

The system block diagram shows how the midUTS main board holds switching matrices and relays that connect your DUT to the test instruments. For testing board assemblies, you’ll need a bed-of-nails test fixture to contact a board’s test points, then the switches route signals to and from the instrumentation. An internal fanless PC runs Windows to control the tests.

Because no automated test system is complete without software, the midUTS uses NI TestStand test executive, which lets you select and sequence individual test programs.

“The midUTS operates under a Windows environment,” Bloomy principal test engineer Jim Kostinden told EE World. “We typically ship these systems with our EFT Module for TestStand (a separate license is required with a 30-day trial license also offered). Based on NI’s TestStand and LabVIEW, the EFT module adds an operator interface/test management UI, SQL database reporting, and measurement-and-hardware abstraction layers. TestStand’s flexibility to execute software test modules written in Python, C/C++, .net, etc. lets engineers use existing code. Combine that with the many instrument drivers available in LabVIEW, this leads to minimal code development and shorter time to deployment.”

Measuring 20 in. W × 36 in. D × 10.5 in. H, the midUTS is small enough to fit on a bench or table.

Applications for the midUTS include:

- robotics and autonomous systems test;

- PCB assembly and subassembly functional test;

- engineering development, manufacturing, quality assurance, and repair depot testing;

- vehicle and factory automation controls, subsystems, computers, and sensors;

- power-supply test

Leave a Reply

You must be logged in to post a comment.