Renishaw’s laser calibration offering has been significantly enhanced with the release of XCal-View’ software, an all new laser data analysis package for use with data captured from the highly successful XL-80, ML10 laser calibration systems and XR20-W rotary axis calibrator.

The new software allows users greater control in their analysis of data than ever before. This is achieved through significant new functionality incorporating simple data manipulation and much greater flexibility in the way that data can be compared, displayed, formatted and viewed.

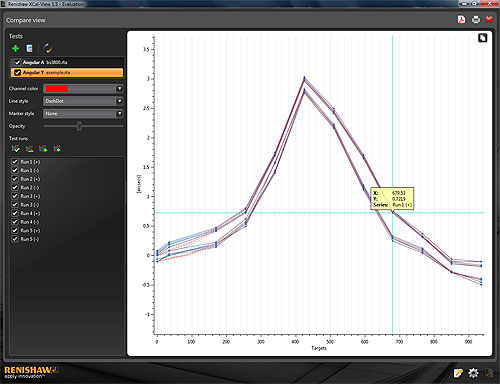

XCal-View compare – allows overlay of data sets from different tests

XCal-View provides analysis of the most universally used measurement types in CNC machine tool calibration with linear, angular, rotary, straightness, squareness and parallelism measurement analysis available to the user. Analysis is supported for data files captured using Renishaw’s LaserXL, RotaryXL and Laser10 software programs ensuring that all Renishaw laser users are catered for.

New features

Some of the new features available with XCal-View include:

- Vastly revised Graphical User Interface (GUI) with an emphasis on ease of use without sacrificing performance or quality of analysis.

- New analysis standards, i.e. ISO230-2(2006) analysis (and the equivalent JIS B and GB/T standards).

- Comparison of data sets new comparative features allow users to compare 2 sets of data including the ability to overlay data graphically. This function is particularly valuable when observing the effects of error compensation.

- Zero Point Shifting an excellent new function that enables the user to offset data so that the displayed and effective zero (0) position is different from that set at the time of data capture. This is particularly useful for users compensating errors in rotary axes.

- Reporting, sharing and exporting new .PDF printing, .PDF reporting and copy’ functionality makes the sharing and extraction of data analysis significantly easier than previously possible

- General error compensation error compensation has been vastly improved and is more effective and easy to use.

All of these new and improved features to be found in XCal-View assure a greatly improved user experience, an increased rate of analysis along with a high degree of user customisation and control. This all makes for a valuable addition to all users of Renishaw laser calibration equipment.

Importantly, XCal-View is the first part of a planned suite of new software covering data capture, analysis and error compensation. Early users will therefore benefit not just from future upgrades of XCal-View but also the close integration with these upcoming, additional modules.

Renishaw

www.renishaw.com

Leave a Reply

You must be logged in to post a comment.