High-speed, non-destructive ultrasonic scanning identifies minute defects in specialty metals and alloys using advanced, phased array scanning acoustic microscopy (SAM).

By Hari Polu, President, OKOS

High-purity metals and alloys such as aluminum, zinc, cobalt, copper, titanium, zirconium, molybdenum, magnesium, and stainless steel are central to many different industries, including electronics, aerospace, and medical devices, among others.

Due to the critical nature of many of the components made from these materials, high-purity alloys need to be highly consistent, with extremely low levels of impurities and contaminations. Consequently, when working with these materials, the quality level has to be extremely high. This, in turn, is driving non-destructive inspection using scanning acoustic microscopy (SAM) to identify small inclusions and other defects as small as 50 microns.

SAM is widely accepted in the semiconductor industry as a failure analysis and reliability detection metrology technique. Now the same technology, with variations in instrumentation and adaptation for different use cases, is being applied to high-purity metals and alloys.

The challenge, however, is performing 100% inspection at sufficient throughput speeds to remove materials with defects that do not meet strict quality requirements. As with other inspection systems, increasing scanning speed traditionally meant sacrificing scanning image resolution. Fortunately, recent advancements in SAM technology have significantly improved throughput speeds and defect detectability.

While a conventional 5 MHz sensor could take up to 45 minutes to inspect an 8 to 10-inch square or disc alloy, an advanced phased array with 64 to 128 sensors and innovative software to render the images reduces inspection time to five minutes with more granular detection of small impurities or defects.

By dramatically increasing inspection speed, the specialty metals industry is no longer limited to selective sample testing during in-process quality control. Although SAM has long been used for this type of inspection, the testing involved a handheld unit or a multi-point inspection. Now it’s more feasible to conduct 100% inspection of the entire surface or interface.

In addition, these advances also facilitate the detection of not just gross defects, but much smaller defects, to drive highly consistent, high-yield products.

Advanced, phased array SAM systems make it possible for specialty metals divisions to move to a higher level of failure analysis because of the level of detection and precision involved. In the past, detecting a 500-micron defect was the goal; now it’s a 50-micron defect, an order of magnitude change. And with high-purity metals, the expectation is to inspect every item, not just a few samples.

Scanning acoustic microscopy

SAM is a non-invasive and non-destructive ultrasonic testing method. The testing is already the industry standard for 100% inspection of semiconductor components to identify defects such as voids, cracks, and the delamination of different layers within microelectronic devices. Now, the same rigor of failure analysis and quality testing is being applied to specialty metals and alloys to detect subsurface flaws, dis-bonds, cracks, and other irregularities.

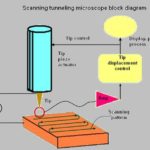

Scanning acoustic microscopy works by directing focused sound from a transducer at a small point on a target object. The sound hitting the object is either scattered, absorbed, reflected, or transmitted. By detecting the direction of scattered pulses as well as the time of flight, the presence of a boundary or object can be determined as well as its distance.

To produce an image, samples are scanned point by point and line by line. Scanning modes range from single-layer views to tray scans and cross-sections. Multi-layer scans can include up to 50 independent layers. Depth-specific information can be extracted and applied to create two- and three-dimensional images without the need for time-consuming tomographic scan procedures and more costly X-rays. The images are then analyzed to detect and characterize flaws such as cracks, inclusions, and voids.

When high throughput is required for 100% inspection, ultra-fast single or dual gantry scanning systems are used along with 128 sensors for phased array scanning. Multiple transducers can also be used to simultaneously scan for higher throughput.

In tests with some companies on a sample of aluminum and steel, the equipment was able to scan the material in three minutes. Before, the tests would take 40 minutes to do just one part.

Some SAM basics

Scanning acoustic microscopy (SAM) is based on the principle of the scanning acoustic microscope. It is one of a number of acoustic microscopy methods, all of which are classed as non-destructive because they use sound waves and thus do not alter or damage the object under test in any way. The sound waves used are generally very high to ultra-high frequency ranging from 5 MHz to 400 MHz and higher. A note about frequencies and image resolution; generally speaking, the higher the frequency the greater the resolution of the image. Conversely, lower frequencies penetrate the object further but do not provide high resolution, so there is a trade-off here.

Specifically, SAM uses a transducer that generates sound waves and focuses these waves at a point on the object under test. To detect a flaw in an object, the scattered sound waves are detected and the time of flight of the wave is calculated, which determines the distance and thereby the imperfection detected in the object.

This process is repeated many times in order to get an accurate image of the material under test. Scanning modes can include single-layer views to more complex cross-sectional views. Scans involving multiple layers can also be used to extract information for creating detailed 2D or 3D images.

The importance of software

As important as the physical and mechanical aspects of conducting a scan are, the software is just as critical to improving the resolution and analyzing the information to produce detailed scans. Multi-axis scan options enable A, B, and C-scans, contour following, offline analysis, and virtual rescanning for composites, metals, and alloys, which result in highly accurate internal and external inspection for defects and thickness measurement via the inspection software.

OKOS decided early on to deliver a software-driven, ecosystem-based solution. The company’s ODIS Acoustic Microscopy software supports a wide range of transducer frequencies from 2.25 to 230 MHz. Estimates are that the company’s software-driven model enables them to drive down the costs of SAM testing while delivering higher-quality of inspection results at faster speeds.

In electronics, aerospace, medical device, and other industries, there is an increasing demand for inspection equipment that can perform non-destructive imaging and materials analysis. With more sensors and advanced software to interpret the information at extremely high resolutions, specialty metals manufacturers can inspect 100% of the materials at a level one to two orders of magnitude better to discover flaws that were previously undetected.

OKOS

www.okos.com

Leave a Reply

You must be logged in to post a comment.