by Johannes Teigelkötter, HBM

Using space vectors in test equipment helps engineers get a clearer, more precise picture of three-phase motor electromagnetics.

With the continuing emphasis on the use of renewable sources of energy, as opposed to the reliance on fossil fuels, advances in induction motor design are allowing for greater efficiencies in both consumer and industrial applications.

The tried and true squirrel cage induction motor has been used in many applications due to its reliability and low maintenance cost, while providing a high power rating. Ac induction motors can be found in simple household appliances like window fans, refrigerators or dishwashers. When paired with a VFD, an ac induction motor allows highly efficient operation of compressors, pumps and blowers in industrial applications.

Perhaps the most notable use of this technology recently is the usage of inverter-fed ac induction motors in the design of electric and hybrid vehicles. The number of electric and hybrid vehicles on roads has steadily increased during the past ten years, with consumers looking to capitalize on the economies offered by such vehicles, or perhaps looking to reduce their personal environmental impact. But, it has not been as simple as throwing an induction motor into an aerodynamically gifted car, all the while reducing greenhouse gas emissions. There is some heavy-duty electromechanical science involved in getting those wheels moving.

Ac induction motors work because of the principal of electromagnetic induction, where an electrical current is generated by passing a metal wire through a magnetic field. Controlling the speed and torque output of ac induction motors can be complex, as magnetic fields and their reactions under many different operating parameters can be difficult to predict and quantify. Thanks to K.P. Kovács, who developed the space vector theory in 1959 to facilitate a mathematical description of three-phase systems, induction motor systems can be modeled by design engineers to achieve smooth control of motor speed and torque.

Space vector theory

Kovács’ space vector theory is often used to describe control methods for induction motors. The electrical and magnetic quantities of a three-phase system cannot be easily defined by traditional mathematical methods, such as plotting those values in relation to an origin and an X and Y axis. The operating parameters for a three-phase induction motor occur in three dimensions; these values can be plotted within the volume of a cube. Of course, that is much easier said than done.

Kovács understood the importance of being able to quantify the parameters of a three-phase system, when at rest and also when rotating. Essentially, his space vector theory takes that three-dimensional cube where those operating parameters exist and transforms them into values that can be mapped onto a two-phase orthogonal system plus a zero sequence system that is present under certain conditions.

The two-phase orthogonal system can then be interpreted as a complex number, which is designated as a space vector. The real and imaginary parts of the complex number correspond to the projections of the complex number displayed as a vector on the α and β axes in the complex plane

Equation 1.01 defines the rules for calculating the complex space vector:

from the three line variables x1, x2 and x3:

where a is a complex rotation operator.

The corresponding zero-sequence system is calculated by:

The real part of the space vector appears on the abscissa α, the imaginary part on the ordinate β. In this figure, the coordinate axes ( α, β) are at rest. The line quantities can be obtained by projecting the space vectors onto the axes when rotated 120° a, b, c.

Data acquisition and processing

While it can be difficult to understand space vector theory or the impact that it has on induction motor design, it is an even more daunting concept to grasp how the operating parameters of a three-phase induction system can be captured and turned into useful data that can be used to increase the efficiency of the drive components of an electric or hybrid vehicle or industrial motor.

To measure the efficiency of electric motors, power analyzers traditionally have been used on the motor input, and torque transducers traditionally on the motor output. The energy loss is the difference between the electrical power and the resulting mechanical power generated by the electric motor.

However, this method doesn’t allow for statements about the causes of the energy loss. Being able to understand how the motor is performing under a wide array of operating parameters in real time is an invaluable resource for developers. It’s the raw measurement data from basic research, not the final results that provide important insight into the process so developers can make the motors more efficient.

While the traditional methods of analyzing motor efficiency provide reliable results, those results are limited in their scope. A power meter can determine efficiency, but it can’t explain that efficiency or help identify approaches that increase efficiency.

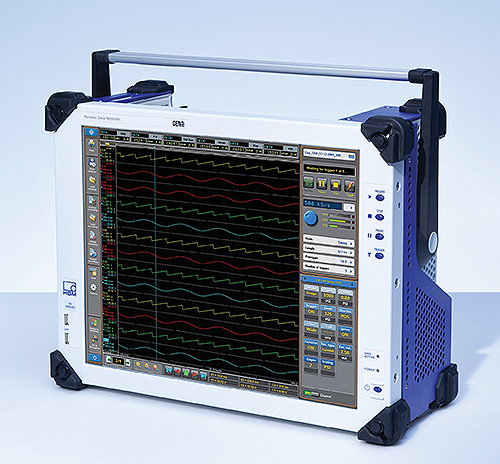

Some data acquisition systems and calculation software packages are designed to do just that. For instance, when paired with HBM’s Genesis High Speed data recorder, HBM’s Perception software is fully capable of gathering three-phase quantities (x1, x2 and x3) and transforming these into space vector quantities.

HBM’s eDrive solution, pairing HBM’s GEN3i High Speed data recorder together with HBM’s T12 torque transducer and Perception software package, continuously stores all relevant data—including currents, voltages, torque, rotational speed and even motor temperature—at high resolution in an integrated system. Additionally, root-mean-square (RMS) values—along with active, apparent and reactive power—are displayed in real time during the measurement, just like with a power meter. Raw data from the motor is captured in real time, allowing detailed analysis during measurement to determine active and reactive power, as well as energy conversion efficiency. Space vectors are determined and transformed with each half cycle, providing an extraordinary amount of usable data for the system designer.

Currents, voltages, torque, rotational speed and even motor temperature can all be monitored in high resolution with a data acquisition and processing package. Developers can also carry out further, more detailed analysis of additional parameters such as fundamental and switching frequency, air-gap moment, slip, iron loss and control behavior.

Given the wealth of information that can be accessed through such systems, developers can optimize efficiencies and performance parameters by being able to model a variety of applications and operating conditions. Motors for specific applications can be designed and manufactured to meet the specific needs of that particular function, rather than end users having motor selection limited to off-the-shelf, standard units.

The efficiencies that can be gained and incorporated into an ever increasing number of ac induction motor applications by using such acquisition and processing packages are seemingly limitless. As the shift away from the gasoline combustion engine to electric and hybrid vehicles progresses, vehicle manufacturers will continue to improve their electric motor efficiencies in an effort to gain a competitive edge. While remaining mostly unseen in the software code of three phase performance calculation software, space vector theory will constantly be called upon by designers looking to optimize motor performance and efficiency.

HBM

www.hbm.com

Leave a Reply

You must be logged in to post a comment.