Some PV solar panels degrade long before others, a fact that makes it tough to estimate the economics of a given solar panel installation. But researchers in Germany are shedding light on solar panel degradation through life tests being run on panels using different PV technologies.

Tests took place on PV panels sitting on the roof of the Max Planck Institute for Chemical Energy Conversion in Germany. The installation includes five inorganic PV technologies: micromorph thin-film silicon, cadmium telluride, copper-indium-gallium-selenium, polycrystalline silicon and amorphous silicon.

Spec sheets for PV panels often provide correction factors for figuring panel efficiency that account for variations in panel temperature. But studies have shown field performance depends on numerous other parameters such as spectral composition, light intensity, and angle of incidence. Such factors affect module performance to differing degrees, depending on the panel composition.

There are also a lot of degradation mechanisms. In poly-Si PV panels, for example, degradation mechanisms include discoloration of the encapsulation material, development of cracks and hot spots, and leakage currents linked to silver paste discoloration. All of these are influenced by environmental conditions.

The IEC has proposed accelerated degradation tests for PV panels, but these are basically infant mortality tests and don’t cover all degradation mechanisms, researchers say.

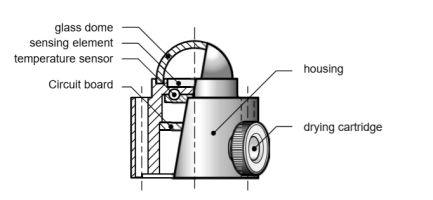

In Germany, all panels are tilted by 20° to the south and each has its own dc/ac converter. A pyranometer measures the in-plane irradiance. There are two temperature sensors for each module type, one at the front and the other at the rear of the panel. Simultaneously, researchers record meteorological data such as atmospheric pressure, temperature, humidity, wind speed, and wind direction.

A pyranometer is a type of actinometer (used for measuring the heating power of radiation) that gauges solar irradiance on a planar surface. It reads out solar radiation flux density (W/m²) from the hemisphere above it. German researchers used a unit from Kipp&Zonen which employs a thermopile (basically thermocouples in series) sensing element.

One complicating factor is that the sensors themselves degrade and must be frequently recalibrated. Nevertheless, researchers noted that technologies based on amorphous silicon (a-Si) and polycrystalline silicon (poly-Si) exhibited the highest output in the five-year test, but panels based on CIGS and CdTe clearly fell behind in output over the years. The worst performer was the micromorph silicon panel (lm-Si). Between 2014 and 2019, the lm-Si panel produced 21% less energy than the a-Si and poly-Si panels, researchers say. Temperature alone doesn’t explain this behavior, as the lm-Si modules recorded the lowest mean and median temperature over the five-year test. The discrepancy between the various panel types hints at degradation phenomena affecting the panels in distinctive ways, researchers say.

Researchers noted seasonal effects as well. The aggregated performance of the poly-Si panels tended to be flat over the whole year, except around the darkest period around the winter solstice. The lm-Si panel performance depended more on the seasons, fluctuating between a summer solstice maximum and a winter solstice minimum. Researchers say the lower performance of the lm-Si panels in the winter can be attributed to the seasonal changes in the composition of the solar spectrum. During summer months, lm-Si panels put out more power thanks to the lower temperature coefficient and thermal annealing.

All in all, researchers found Si-based panels degraded at a median rate of –0.3% per annum in the first 3 years after installation, in line with the results of other tests. But CdTe panels seemed to perform worse than what other tests have revealed, and CIGS panels seem to be improving. Researchers say the most concerning result might be that of commercial lm-Si panels which degraded at a mean rate of about –17.7% over five years.

Leave a Reply

You must be logged in to post a comment.