Four finalists were announced Friday for the inaugural LEAP Awards’ Test & Measurement Category, comprising a broad array of new advances in instrumentation technology. The competition was scored by a panel of independent technical/engineering judges.

This year’s inaugural LEAP Awards competition honored ground-breaking new products that set a new standard for innovation. Judges rated candidates on categories that included societal impact, industry impact, technical sophistication, creativity, and value to customers.

Three judges chose finalists for the T&M category: Geoffrey Haigh, Principal/Senior Partner, Haigh Consulting LLP; Sam John,

President, Innovative Products Inc.; and Bill Schweber, Engineer, Author, Editor, Jaffa Engineering.

Geoffrey Haigh holds 31 patents and was the originator and inventor of the ADI ICoupler technology while working for Analog Devices Inc. He also developed equipment now on Mars, built into Mars rovers.

Sam John designs and manufactures custom-built automatic industrial machines. He previously worked for Sorb Technology (now Fresenius) and Akzo-Nobel. He holds an MBA from Oklahoma City University, a Master’s in ME from the University of Oklahoma and a BS in ME from the University of Calicut.

Bill Schweber has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. He has also edited the respected technical journal published by Analog Devices Inc. He has also worked at Instron Corp. doing analog- and power-circuit design and systems integration for materials-testing machine controls. His MSEE is from the University of Massachusetts and his BSEE from Columbia University.

Judges chose four finalists. The overall winner of the T&M category will be announced at an awards dinner on December 11, 2018 in Costa Mesa, Calif.

The finalists, in no particular order, were Anritsu with its MP1900A BERT signal quality analyzer-R; Mentor, a Siemens Business, with its T3Ster and FloTherm and FloTherm XT calibration; and Tektronix with two entries – the DAQ6510 Data Acquisition and Multimeter System; and the 6 Series MSO mixed signal oscilloscope.

Anritsu’s Signal Quality Analyzer-R MP1900A series is a high- performance bit error rate tester (BERT) with a flexible 8-slot modular design. It supports measurement applications with an internal 32 Gbit/sec Multi-channel pulse pattern generator (PPG), error detector (ED), and Jitter/Noise addition modules for signal integrity analysis of increasingly faster devices used in next-generation data center applications. It has best-in-class typical low intrinsic jitter data output of 115 fsec rms and typical high input sensitivity of 15 mV (eye height).

performance bit error rate tester (BERT) with a flexible 8-slot modular design. It supports measurement applications with an internal 32 Gbit/sec Multi-channel pulse pattern generator (PPG), error detector (ED), and Jitter/Noise addition modules for signal integrity analysis of increasingly faster devices used in next-generation data center applications. It has best-in-class typical low intrinsic jitter data output of 115 fsec rms and typical high input sensitivity of 15 mV (eye height).

Functions for evaluating the physical layer of high-speed interfaces are provided, as well. The MP1900A supports PCI Express (PCIe) Gen 1 to Gen 4, as well as upcoming Gen 5 without the need to upgrade hardware. The BERT has a built-in Link Training/LTSSM analysis function that supports all-in-one measurement of high-speed network interfaces such as 200/400 GbE, and bus interfaces such as PCIe.

PAM4 signal formats are being adopted for next-generation 200 GbE and 400 GbE standards but since the amplitude of three Eyes representing four levels is one third that of an NRZ signal, the receiver circuit must have adequate input sensitivity performance. To evaluate input sensitivity performance appropriately, as with NRZ signals, it is important to analyze using a test signal that has been calibrated by adjusting the jitter and emphasis to match the input sensitivity test standards. Since the MP1900A module supports simultaneous addition of two types of SJ, as well as RJ, BUJ, and SSC up to 32 Gbit/s, it is ideal for jitter tolerance according to various standards.

Receiver tests on high-speed interconnects require that the link status be established using LTSSM before DUT BER tests are performed. The MP1900A supports verification of the link status, and has an LTSSM analysis function for advanced troubleshooting.

The Mentor T3Ster and FloTHERM technologies enable suppliers to  design better LEDs, power semiconductor and IC packages, create accurate simulation models, and verify systems for proper heat management. T3Ster is an advanced thermal transient tester for thermal characterization of semiconductor device packages, producing several types of package thermal characteristics in just a few minutes. FloTHERM, a powerful 3D computational fluid dynamics (CFD) software, predicts airflow and heat transfer in and around electronic equipment.

design better LEDs, power semiconductor and IC packages, create accurate simulation models, and verify systems for proper heat management. T3Ster is an advanced thermal transient tester for thermal characterization of semiconductor device packages, producing several types of package thermal characteristics in just a few minutes. FloTHERM, a powerful 3D computational fluid dynamics (CFD) software, predicts airflow and heat transfer in and around electronic equipment.

T3Ster and its related data processing software is the most advanced, commercially available system that implements the latest thermal testing standard (JESD51-14) for the measurement of junction-to-case thermal resistance for wide class of semiconductor device packages. A positive consequence of the Mentor Graphics MicReD realization of the JESD51-14 standard is that, besides the required standard thermal metric, a dynamic compact thermal model of the part being characterized is also automatically generated in a format directly applicable in the FloTHERM software.

FloTHERM is the first commercial CFD tool that provides a direct interface to physical testing, which allows validation of detailed CFD models of packages or creation of package compact models if detailed CFD modeling of the part is not supported by its manufacturer. T3Ster technology is comprised of a flexible range of hardware, including the thermal transient tester station itself and numerous accessories (thermostat, booster, thermocouple pre-amplifiers, JEDEC standard still-air chambers, test-boards and special fixtures, e.g., for TIM measurements).

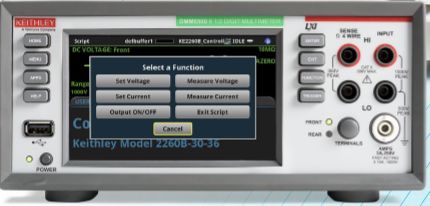

The first of the two Tektronix finalists comes from Tek’s Keithley operation. While most digital multimeters (DMMs) can take static or slowly changing measurements, they cannot adequately capture the short duration load current bursts that occur when the wireless device transmits. The Keithley DMM6500 addresses this need by having a 16-bit sampling A-to-D converter for digitizing current or voltage measurements at up to 1 MSample/sec. This 1 µsec sampling interval allows capture of ultra-fast load current bursts and helps to show any unwanted transients in the load current. The digitizing functions cover the same measurement ranges as the DMM’s traditional dc voltage and current functions of 100 mV to 1,000 V or 10 µA to 3 A. Digitizing sensitivity is a low 10 µV and 10 nA for voltage and current, respectively. The DMM6500 also features a full 5 in. (12.7 cm) multi-touch screen display for interacting with recorded data on the instrument with fully featured graphing and data analysis tools. Collecting logged data can be as simple as inserting a USB drive or transmitting readings during the test to a computer.

operation. While most digital multimeters (DMMs) can take static or slowly changing measurements, they cannot adequately capture the short duration load current bursts that occur when the wireless device transmits. The Keithley DMM6500 addresses this need by having a 16-bit sampling A-to-D converter for digitizing current or voltage measurements at up to 1 MSample/sec. This 1 µsec sampling interval allows capture of ultra-fast load current bursts and helps to show any unwanted transients in the load current. The digitizing functions cover the same measurement ranges as the DMM’s traditional dc voltage and current functions of 100 mV to 1,000 V or 10 µA to 3 A. Digitizing sensitivity is a low 10 µV and 10 nA for voltage and current, respectively. The DMM6500 also features a full 5 in. (12.7 cm) multi-touch screen display for interacting with recorded data on the instrument with fully featured graphing and data analysis tools. Collecting logged data can be as simple as inserting a USB drive or transmitting readings during the test to a computer.

The 6 Series MSO mixed signal oscilloscope from Tektronix extends the performance threshold of midrange oscilloscopes to 8 GHz and delivers a 25 GS/sec sample rate simultaneously on all 4 channels – an industry first for this class of oscilloscope.

the performance threshold of midrange oscilloscopes to 8 GHz and delivers a 25 GS/sec sample rate simultaneously on all 4 channels – an industry first for this class of oscilloscope.

The new 6 Series MSO also boosts measurement confidence with its low-noise inputs especially at the highest sensitivity settings where it matters most. For example, modern embedded designs require clean, precisely-controlled DC power supplies to feed ASIC and FPGA devices. For such applications, the 6 Series MSO enables designers to measure dc power rails with more resolution and accuracy, reducing the time it takes to understand high-frequency influencers on power rails in a design.

To meet the need for more insight on faster signals, the 6 Series MSO incorporates a new low-noise preamplifier ASIC, the TEK061, that dramatically lowers noise, especially on signals that are in the hundreds of millivolts peak-to-peak. The instrument delivers 16-bit resolution at 200 MHz when using the High Res mode. This means that not only can designers see the interfering signals on their power rail, but they can measure them with a level of accuracy, that until now has not been possible on a scope.

Leave a Reply

You must be logged in to post a comment.